| Hosts | 1 |

| Iron box | 1 |

| Leverage | 2 |

| Weight(professional level) | 12 |

| Advanced power cord | 1 |

| Oil box | 2 |

| Custom diamond oil stone | 2 |

| Bushing | 2 |

| Standard steel ball for experiment | 50 |

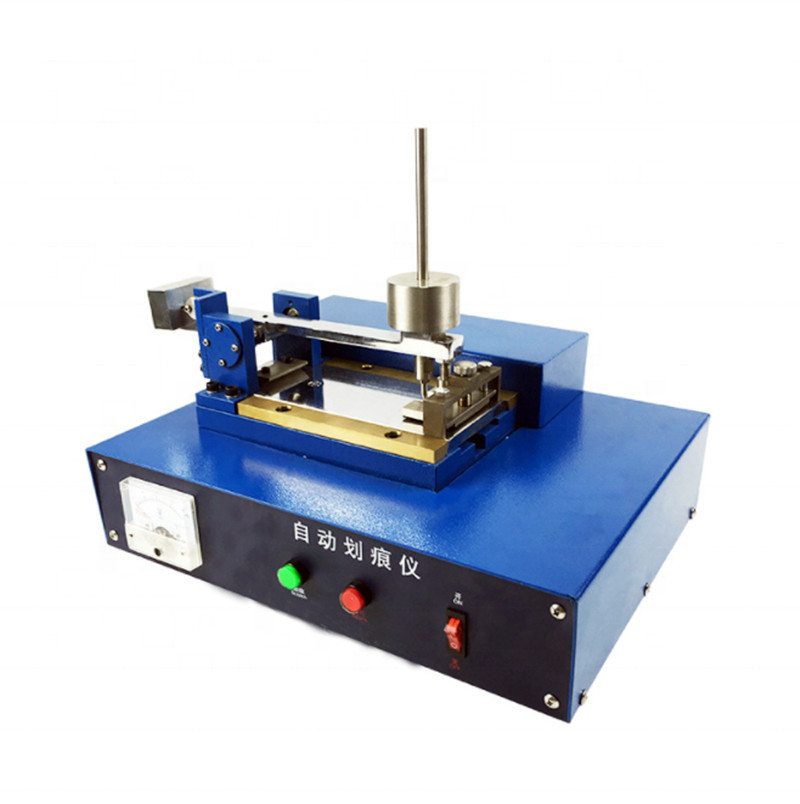

UP-1013 Lubricating Abrasion Analyzer Oil Friction Tester

Looking for a reliable factory for your lubricating abrasion analysis needs? Choose our {UP-1013 Lubricating Abrasion Analyzer Oil Friction Tester} for accurate results.

Request a QuotePRODUCTS DETAILS

Hot Products

UP-6016 Intelligent line drying time recorder

5750 Linear Abrasion Resistance Tester

UP-6010 Automatic Film Applicator,Vacuum coating machine for laboratory

UP-6004 Rub Resistance Tester, Dry and Wet Ink Printing Rub Durability Test Machine

UP-6041 Digital paper thickness tester TAPPI T 411

UP-3013 Charpy Impact Tester

Auto safety glass pendulum impact tester with double tire impactor

UP-6007 Coating Automatic Scratch Tester,Surface scratch tester

UP-6013 ASTM D4541D7234, ISO 462416276 Automatic Coating Degumming Tester,Pull-off Adhesion Tester

UP-6036 Package Leak and Seal Strength Detector

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours