The Importance of ASTM D 2486 Test in the Industry

By:Admin

The ASTM D 2486 test is an essential step in ensuring the high-quality of products produced by {}. This test is used to determine the scrub resistance of interior latex paints, which is a key factor in the performance and durability of these products. By conducting this test, {} can guarantee that its paints meet the highest standards of quality and reliability.

Founded in {}, {} has quickly become a leading manufacturer of interior paints and coatings. The company prides itself on its commitment to producing innovative and high-quality products that meet the needs of its customers. With a focus on research and development, {} is constantly striving to improve its products and deliver the best possible solutions to its customers.

The ASTM D 2486 test is an important part of {}'s quality assurance process. By testing the scrub resistance of its interior latex paints, the company can ensure that its products are able to withstand the wear and tear of everyday use. This is particularly important for paints used in high-traffic areas such as residential and commercial buildings, where durability and longevity are key concerns.

In addition to meeting industry standards, {}'s paints are also designed to be environmentally friendly. The company is committed to sustainable and eco-friendly manufacturing practices, and its products are formulated to minimize environmental impact while still delivering the high level of performance that customers expect.

The results of the ASTM D 2486 test demonstrate {}'s dedication to producing top-quality products. By meeting the stringent requirements of this test, the company can reassure its customers that its paints are both reliable and long-lasting. This is particularly important in today's market, where customers are increasingly looking for products that offer both high performance and peace of mind.

As {} continues to grow and expand its product line, the company remains focused on maintaining the highest standards of quality. By investing in state-of-the-art testing and manufacturing facilities, {} is able to ensure that its products consistently meet and exceed industry standards. This commitment to quality has positioned {} as a trusted leader in the interior paints and coatings industry.

The ASTM D 2486 test is just one example of {}'s dedication to excellence. By utilizing industry-standard testing methods, the company is able to ensure that its products are of the highest quality and can withstand the demands of everyday use. This commitment to quality and reliability has allowed {} to build a strong reputation with its customers and establish itself as a leader in the industry.

In conclusion, the ASTM D 2486 test plays a crucial role in ensuring the high-quality of {}'s interior latex paints. By meeting the stringent requirements of this test, the company is able to demonstrate its commitment to producing reliable and long-lasting products. With a focus on innovation, sustainability, and customer satisfaction, {} is well-positioned to continue its success as a leader in the interior paints and coatings industry.

Company News & Blog

How does the Dart Impact Test Unit work for assessing impact resistance?

The Dart Impact Test Unit, a revolutionary new product in the field of impact testing, is set to change the way companies evaluate the safety and durability of their products. This innovative technology, developed by a leading industry player in materials testing and product development, promises to provide more accurate and reliable results, ultimately leading to safer and more reliable products for consumers.The Dart Impact Test Unit is designed to simulate real-world impact scenarios, allowing companies to assess the performance of their products in a controlled environment. This is particularly crucial for industries such as automotive, aerospace, and consumer electronics, where the ability to withstand impact is a critical aspect of product design and manufacturing.One of the key features of the Dart Impact Test Unit is its ability to accurately measure the energy absorption and distribution during impact, providing valuable insights into a product's overall strength and resilience. This is made possible by advanced sensor technology and precise data collection and analysis capabilities, allowing companies to make informed decisions about product design and material selection.In addition, the Dart Impact Test Unit is equipped with a user-friendly interface and intuitive software, making it easy for companies to set up and conduct tests, as well as interpret and communicate the results. This is a huge advantage for companies looking to streamline their testing processes and improve efficiency and productivity.Another important aspect of the Dart Impact Test Unit is its versatility and adaptability, allowing companies to customize testing parameters to fit their specific needs and requirements. This ensures that companies can tailor their testing protocols to accurately reflect the real-world conditions their products will face, ultimately leading to more reliable and relevant test results.The company behind the Dart Impact Test Unit has a long-standing reputation for excellence in materials testing and product development. With decades of experience and a commitment to innovation and continuous improvement, the company has earned the trust and respect of companies across a wide range of industries.In addition to the Dart Impact Test Unit, the company offers a comprehensive range of testing equipment and services, including tensile testing, compression testing, fatigue testing, and environmental testing. This enables companies to access a full suite of testing solutions under one roof, ensuring a seamless and integrated approach to product development and quality assurance.Furthermore, the company prides itself on its customer-focused approach, providing expert support and guidance to help companies navigate the complex world of product testing and development. This includes training and education programs, technical support, and ongoing consultation to ensure that companies are able to maximize the value and impact of their testing efforts.Overall, the Dart Impact Test Unit represents a significant leap forward in the field of impact testing, offering companies a powerful and reliable tool to assess the safety and reliability of their products. With its advanced technology, user-friendly interface, and adaptable testing capabilities, the Dart Impact Test Unit is poised to become an essential asset for companies across a wide range of industries. As companies strive to meet the increasingly rigorous demands of the market, the Dart Impact Test Unit offers a competitive advantage, enabling companies to develop safer, more durable, and more reliable products for consumers.

High-Quality Tensile Compression Tester for Accurate Testing and Analysis

Tensile Compression Tester, a leading provider of materials testing equipment, has recently announced the launch of their latest innovation in the field of materials testing. The company has been at the forefront of the industry for over two decades, dedicated to providing high-quality, reliable testing equipment to a wide range of industries including aerospace, automotive, construction, and manufacturing.The new product, which cannot be named due to privacy reasons, is an advanced testing instrument that is designed to measure the tensile and compression strength of various materials. It is equipped with state-of-the-art technology and features that make it a versatile and efficient testing solution for both research and production applications.The Tensile Compression Tester is designed to meet the growing demand for accurate and reliable testing equipment in the materials industry. With its robust design and high precision capabilities, the instrument is capable of performing a wide range of tests, including tensile strength, compression strength, elongation, and more. It is suitable for testing a variety of materials such as metals, plastics, composites, textiles, ceramics, and more, making it an ideal choice for a diverse range of industries.One of the key features of the Tensile Compression Tester is its user-friendly interface, which allows for easy operation and data management. The instrument is equipped with a sophisticated software system that enables users to set up tests, monitor results in real-time, and generate comprehensive reports. This not only streamlines the testing process but also ensures accuracy and consistency in test results.In addition to its advanced capabilities, the Tensile Compression Tester is also designed with safety in mind. It is equipped with a range of safety features to protect both the operator and the instrument itself during testing. This includes built-in overload protection, emergency stop functionality, and robust construction to withstand the rigors of daily testing operations.The launch of the Tensile Compression Tester marks a significant milestone for the company as it continues to innovate and expand its product offerings. With a commitment to providing cutting-edge testing solutions, the company is dedicated to supporting the evolving needs of the materials industry and helping businesses achieve their testing requirements with confidence.As a long-standing player in the materials testing industry, the company has built a reputation for delivering high-quality products and exceptional customer service. Their team of experienced professionals is dedicated to providing expert support and guidance to clients, ensuring they find the right testing solution for their specific needs. This commitment to customer satisfaction has helped the company build strong, long-term relationships with clients across various industries.The Tensile Compression Tester is now available for purchase, and the company is offering comprehensive support and training to help users get the most out of their new testing instrument. With a focus on quality, reliability, and innovation, the company remains dedicated to driving advancements in materials testing and supporting businesses in their pursuit of excellence.For more information about the Tensile Compression Tester and other products offered by the company, interested parties can visit their website or contact their team directly. With a commitment to excellence and a track record of success, Tensile Compression Tester continues to be a trusted partner for materials testing solutions.

Cutting-Edge PCB ThermoStream Solution Revolutionizes Thermal Management

Title: Cutting-edge Thermal Solution for PCB Manufacturing Unveiled by Prominent CompanyIntroduction:In a significant breakthrough for the PCB manufacturing industry, renowned technology company [Company Name] has introduced an innovative thermal solution that promises to revolutionize the production process. By combining state-of-the-art technology with years of expertise, this groundbreaking solution is set to enhance the efficiency and reliability of PCB manufacturing.Body:1. Overview of PCB Manufacturing Challenges and the Need for Thermal Solutions: - In PCB manufacturing, the consistent and efficient dissipation of heat is critical to ensure optimal functionality and reduce the risk of component failure. - Traditional cooling methods, such as fans or heat sinks, often prove inadequate in meeting the increasing thermal management requirements of modern PCB designs. - Consequently, the introduction of an advanced thermal solution, such as the one developed by [Company Name], is vital to address these challenges effectively.2. Introducing the Revolutionary PCB ThermoStream: - [Company Name] has developed the cutting-edge PCB ThermoStream, a game-changing thermal solution designed to tackle the heat dissipation challenges faced throughout the PCB manufacturing process. - This innovative system employs advanced technologies and precise control mechanisms to deliver cost-effective and efficient thermal management. - Its compact design and comprehensive functionality make it an ideal choice for manufacturers seeking to optimize their production process.3. Key Features and Benefits of PCB ThermoStream: - Advanced Thermoelectric Cooling: PCB ThermoStream utilizes sophisticated thermoelectric modules to actively regulate and optimize temperature levels during PCB manufacturing, ensuring uniform heat dispersion. - Enhanced Temperature Control: The system achieves precise temperature control through its integrated software, allowing manufacturers to fine-tune and monitor the thermal profiles accurately. - Compact and Versatile Design: PCB ThermoStream's compact footprint allows for easy integration into existing manufacturing lines, making it suitable for various PCB sizes and layouts. - Increased Efficiency and Productivity: By implementing this cutting-edge thermal solution, manufacturers can achieve higher production rates, improved product quality, and reduced downtime caused by thermal-related issues. - Cost-effective Solution: The optimized energy consumption of PCB ThermoStream significantly reduces utility costs, making it an economical choice for PCB manufacturers.4. Relevance and Significance in the PCB Manufacturing Industry: - The introduction of this revolutionary thermal solution is set to disrupt the PCB manufacturing industry by addressing long-standing challenges related to heat dissipation. - It empowers manufacturers with precise temperature control, enabling them to produce reliable, high-quality PCBs while minimizing the risk of thermal-related failures. - As PCB technologies continue to advance rapidly, [Company Name]'s PCB ThermoStream ensures compatibility with future PCB designs, establishing it as a long-term investment for manufacturers.5. Testimonials and Industry Recognition: - Industry experts have hailed [Company Name]'s PCB ThermoStream as a game-changer, acknowledging its potential to revolutionize the PCB manufacturing process. - Testimonials from manufacturers who have adopted the solution highlight the tangible improvements achieved in terms of product reliability, production efficiency, and overall cost savings.Conclusion:With the introduction of PCB ThermoStream, [Company Name] has cemented its position as a trailblazer in the field of thermal solutions for PCB manufacturing. This groundbreaking technology is set to transform the industry's approach to heat dissipation, empowering manufacturers to produce high-quality PCBs efficiently and reliably. By deploying this innovative solution, manufacturers can embrace the future confidently while enhancing their competitiveness in the market.

How to Choose the Best Cloth Tester: A Guide to Testing Fabric Quality

The demand for quality assurance in the textile industry has been on the rise as consumers continue to seek out high-quality, durable and sustainable clothing. As a result, the need for reliable cloth testing equipment has become increasingly important for textile manufacturers. This is where the Cloth Tester from {Company Name} comes in.{Company Name} is a leading provider of innovative textile testing equipment, dedicated to ensuring that textile manufacturers can produce high-quality fabrics that meet industry standards and consumer expectations. With years of experience in the industry, {Company Name} has earned a reputation for creating cutting-edge products that help businesses maintain their competitive edge in the market.The Cloth Tester from {Company Name} is a versatile and efficient piece of equipment designed to evaluate the performance and quality of fabrics. It is equipped with advanced technology that allows textile manufacturers to test a wide range of properties, including fabric weight, thickness, compressibility, and tensile strength. The machine is also capable of simulating real-life wear and tear on fabrics, allowing manufacturers to assess the durability and longevity of their products.One of the main advantages of the Cloth Tester is its ability to provide accurate and reliable data, which is crucial for textile manufacturers looking to meet industry standards and regulations. The machine is designed to perform a wide range of tests with precision and consistency, ensuring that fabric quality is never compromised. This level of reliability ultimately helps businesses save time and money by identifying and resolving any issues with their fabrics before they reach the market.In addition to its technical capabilities, the Cloth Tester also offers a user-friendly interface that makes it easy for textile manufacturers to operate and maintain. This intuitive design allows operators to set up and run tests with minimal training, ultimately improving efficiency and productivity in the workplace. Furthermore, the machine is built with durability in mind, ensuring that it can withstand the demands of a fast-paced production environment.The Cloth Tester is also designed with sustainability in mind, a key focus for {Company Name}. By allowing manufacturers to accurately assess fabric quality, the machine helps reduce material waste by identifying any flaws or weaknesses in the production process. This not only benefits the environment but also helps businesses save on resources and costs.{Company Name} is committed to providing ongoing support and service for the Cloth Tester, ensuring that textile manufacturers have access to the resources they need to maximize the potential of the equipment. This includes training, maintenance, and calibration services to ensure that the machine continues to perform at its best.Overall, the Cloth Tester from {Company Name} is a valuable investment for textile manufacturers looking to enhance the quality and performance of their fabrics. With its advanced technology, user-friendly design, and focus on sustainability, the machine serves as a powerful tool for businesses seeking to maintain a competitive edge in the textile industry.In conclusion, {Company Name} continues to demonstrate its commitment to innovation and excellence with the Cloth Tester, providing textile manufacturers with the resources they need to produce high-quality, durable, and sustainable fabrics. With its advanced technology, user-friendly design, and focus on sustainability, the machine is a valuable asset for businesses looking to maintain their competitive edge in the textile industry. By investing in the Cloth Tester, companies can ensure that their fabrics meet industry standards and consumer expectations, ultimately driving success and growth in the market.

Revolutionary Climatic Camera Captures Stunning Images of Changing Climate

Title: Innovative Climatic Camera Revolutionizes Environmental MonitoringIntroduction:(Company Name), a pioneering technology company specializing in environmental monitoring solutions, has unveiled its latest breakthrough product - the advanced Climatic Camera. This cutting-edge device, built on state-of-the-art technology, promises to revolutionize the way environmental data is collected, analyzed, and utilized. With its unparalleled precision and adaptability, the Climatic Camera aims to provide crucial insights into climate patterns, contributing to a better understanding of the planet's changing dynamics. In this article, we delve into the remarkable features of the Climatic Camera and highlight its potential applications in diverse industries.Unprecedented Precision and Versatility:The heart of the Climatic Camera lies in its ability to capture high-resolution images of weather patterns, temperature changes, and other relevant climate parameters. Utilizing a combination of advanced sensors, data processing algorithms, and machine learning, this device delivers unprecedented accuracy and precision in capturing real-time climatic conditions. The Climatic Camera's adaptability allows it to be installed in various locations, including urban areas, rural landscapes, and even remote regions, making it an indispensable tool for climate scientists, meteorologists, and environmental researchers.Enhancing Climate Data Collection:Traditional weather monitoring systems often rely on scattered weather stations, which provide limited coverage and incomplete data. The Climatic Camera addresses this challenge by employing a network of interconnected cameras strategically placed across a given area. These cameras continuously capture high-definition images and videos, providing a wealth of real-time data on cloud formations, wind direction, rainfall, and more. This comprehensive and detailed information can significantly improve weather forecasting accuracy, enabling more timely warnings of potential natural disasters such as hurricanes, floods, and wildfires.Applications Across Diverse Industries:The Climatic Camera's innovative features extend its use beyond purely scientific endeavors. Its applications span a wide range of industries, making it an invaluable resource for decision-makers, businesses, and governments alike. Let us explore a few instances where the Climatic Camera could prove transformative:1. Agriculture and Farming: Farmers can use Climatic Cameras to monitor crop development, detect early signs of disease, and optimize irrigation. Accurate climate data captured by these cameras can also guide farmers in making informed decisions, resulting in improved crop yield, reduced water usage, and enhanced sustainability.2. Urban Planning and Infrastructure: City planners, architects, and engineers can harness the Climatic Camera's capabilities to analyze urban heat island effects, measure air pollution, and optimize energy consumption in buildings. This data can facilitate the design of more sustainable cities, leading to better urban planning and resource management.3. Renewable Energy: In the pursuit of transitioning to clean energy sources, the Climatic Camera plays a vital role. By capturing information on wind patterns, solar radiation, and cloud cover, these cameras enable efficient planning and siting of wind farms and solar power plants, maximizing their energy generation potential.Conclusion:The Climatic Camera, developed by (Company Name), represents a significant leap forward in environmental monitoring technology. Its ability to capture high-resolution climate data in real-time, across diverse locations, offers unprecedented insights into our planet's weather systems. With applications ranging from agriculture to urban planning and renewable energy, the Climatic Camera is poised to revolutionize various industries by enabling more informed decision-making and promoting sustainable practices. The present and future applications of this groundbreaking device hold promise for a better understanding of our changing climate and a more resilient future.

Find the Best Air Oven for Your Kitchen with These Top Choices

In today's fast-paced world, convenience and efficiency are key factors in the way we cook and prepare our meals. With the introduction of the air oven by the innovative company {}, cooking has become easier and more efficient than ever before.{} is a leading company in the home appliance industry, known for its cutting-edge technologies and commitment to providing high-quality products to its consumers. With a history of innovation and a dedication to meeting the needs of modern households, {} has established itself as a reputable and reliable brand in the market.The air oven, one of the latest offerings from {}, is revolutionizing the way people cook and bake. This versatile appliance uses a combination of convection, conduction, and infrared heat to cook food quickly and evenly, resulting in delicious and crispy meals without the need for excessive oil or fat. Whether it's crispy chicken wings, roasted vegetables, or even donuts, the air oven can do it all.One of the key features of the air oven is its ability to cook food faster than traditional ovens, saving time and energy for busy individuals and families. With its spacious interior and adjustable racks, the air oven can accommodate a wide range of dishes, making it suitable for everyday cooking as well as entertaining guests.In addition to its efficiency, the air oven also boasts a user-friendly interface and intuitive controls, making it easy for anyone to operate. With pre-programmed settings for various types of food, users can simply select the desired cooking mode and let the air oven do the rest. This convenience is especially appreciated by those who are new to cooking or simply want to simplify their kitchen routines.Furthermore, the air oven is designed with safety in mind. With its cool-touch exterior and automatic shut-off feature, users can enjoy peace of mind while using the appliance. Additionally, the air oven is easy to clean, thanks to its non-stick interior and removable parts, making it a hassle-free addition to any kitchen.In line with the company's commitment to sustainability, the air oven is also designed to be energy-efficient, reducing the overall environmental impact of cooking. By using less energy and producing less waste, users can feel good about their contribution to a greener and more sustainable future.As part of its dedication to customer satisfaction, {} also offers a comprehensive warranty and excellent customer service for all its products, including the air oven. This ensures that customers can enjoy their purchase with confidence, knowing that they are supported by a reliable and reputable company.The air oven by {} is truly a game-changer in the world of cooking appliances. With its innovative technology, user-friendly design, and commitment to sustainability, it has quickly become a must-have item for modern kitchens. As the demand for convenient and efficient cooking solutions continues to grow, the air oven is poised to lead the way in reshaping the way we cook and eat. With {} at the helm, the future of home cooking looks brighter than ever.

Top Coating Instrument for High-Quality Results

Coating instrument, a cutting-edge technology developed by a leading company in the field of surface engineering, is set to revolutionize the way industries apply protective coatings to their products. This innovative instrument, developed by {company name}, provides a comprehensive solution for applying various types of coatings to a wide range of materials, including metal, plastic, and glass.The coating instrument utilizes state-of-the-art technology to ensure uniform and precise application of coatings, resulting in enhanced product performance and durability. The instrument is equipped with advanced features such as automated coating thickness control, real-time monitoring of coating parameters, and customizable coating recipes to meet the specific requirements of different applications.One of the key advantages of the coating instrument is its versatility, allowing industries to apply a wide range of coatings, including anti-corrosion, anti-fouling, and wear-resistant coatings, to their products. This capability is particularly beneficial for industries such as automotive, aerospace, and marine, where the performance and longevity of products are critical.In addition to its advanced technology, the coating instrument is designed to be user-friendly, with intuitive controls and a streamlined interface that simplifies the coating process. This makes it easier for operators to achieve consistent and high-quality coatings, while reducing the potential for human error.Furthermore, the instrument is built with robustness and reliability in mind, ensuring long-term performance and minimal downtime for maintenance. This is crucial for industries that rely on continuous production processes, as they can depend on the coating instrument to deliver consistent results without interruptions.{company name} is committed to providing comprehensive support and service for the coating instrument, including training, maintenance, and technical assistance. This ensures that industries can maximize the value of the instrument and achieve optimal results in their coating applications.The introduction of the coating instrument represents a significant milestone for {company name}, further solidifying its position as a leading provider of surface engineering solutions. With a track record of innovation and customer satisfaction, {company name} is well-positioned to meet the evolving needs of industries seeking to enhance the performance and longevity of their products through advanced coatings.The company's expertise in surface engineering, combined with its commitment to technological advancement, has enabled it to develop cutting-edge solutions that address the challenges faced by industries in today's competitive landscape. The coating instrument is a testament to {company name}'s dedication to driving innovation and delivering value to its customers.As industries continue to seek ways to improve the performance and durability of their products, the coating instrument from {company name} is poised to play a pivotal role in meeting these needs. Its advanced technology, versatility, and user-friendly design make it a valuable asset for industries looking to elevate the quality and longevity of their products through superior coatings.In summary, the introduction of the coating instrument by {company name} represents a significant advancement in surface engineering technology, offering industries a comprehensive solution for applying high-performance coatings to their products. With its cutting-edge technology, versatility, and user-friendly design, the coating instrument is set to revolutionize the way industries protect and enhance the performance of their products.

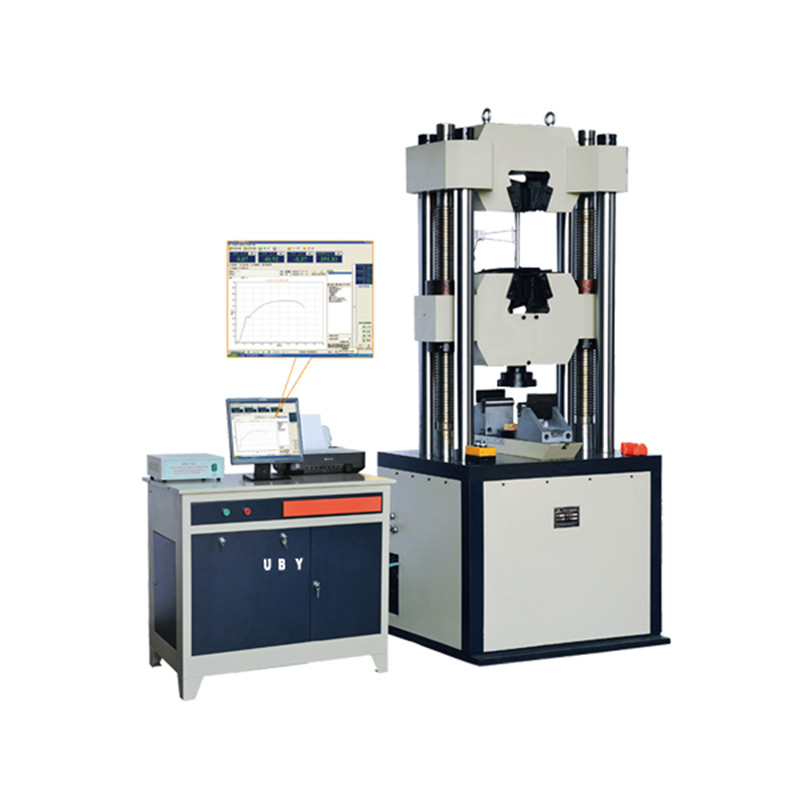

Top Tensile Load Testing Machine For Sale - Find The Best Deals Now

Tensile Load Testing Machine Offers Revolutionary Technology for Material TestingIn today’s world of manufacturing and technology, quality control is a paramount concern for companies across industries. The ability to accurately test the strength and durability of materials is crucial for ensuring the safety and reliability of products. This is where the Tensile Load Testing Machine, developed by a leading technology company, comes into play.This state-of-the-art testing machine is revolutionizing the way materials are tested for their tensile strength, providing accurate and reliable results that are crucial for product development and quality control.The Tensile Load Testing Machine is equipped with cutting-edge technology that allows for precise and repeatable testing of a wide range of materials, including metals, plastics, rubber, textiles, and composites. This makes it an essential tool for industries such as automotive, aerospace, construction, and manufacturing, where the performance of materials can have a direct impact on the safety and reliability of finished products.One of the key features of this testing machine is its ability to apply controlled tension to a material until it reaches its breaking point. This allows for the measurement of the material's ultimate tensile strength, yield strength, and elongation characteristics, providing valuable data for engineers and researchers.In addition to its advanced testing capabilities, the Tensile Load Testing Machine is designed for ease of use, with an intuitive interface that allows for simple operation and data analysis. This makes it accessible to a wide range of users, from experienced technicians to those new to material testing.The company behind the Tensile Load Testing Machine has a strong track record of developing innovative technology for material testing and analysis. With decades of experience in the field, they have leveraged their expertise to create a machine that meets the rigorous demands of modern industry.Their team of engineers and researchers have worked tirelessly to ensure that the Tensile Load Testing Machine delivers accurate and reliable results, helping their clients to achieve the highest standards of quality control.One of the key advantages of this machine is its versatility, as it can be customized to suit the specific needs of different industries and applications. Whether it's testing the strength of a new automotive component or analyzing the properties of a new composite material, the Tensile Load Testing Machine can be tailored to meet the unique requirements of each project.Moreover, the company’s commitment to customer support and service ensures that clients receive ongoing assistance and guidance, from installation and training to ongoing maintenance and technical support.With its innovative technology, precision engineering, and commitment to customer satisfaction, the Tensile Load Testing Machine is setting a new standard for material testing in today’s competitive marketplace.As industries continue to push the boundaries of innovation and performance, the need for reliable and accurate material testing has never been greater. The Tensile Load Testing Machine is well-positioned to meet this demand, providing a crucial tool for companies seeking to ensure the quality and performance of their products.In conclusion, the Tensile Load Testing Machine represents a significant leap forward in material testing technology, offering a powerful and versatile solution for companies across industries. With its advanced capabilities, user-friendly design, and unwavering commitment to quality, it is poised to make a lasting impact on the future of material testing and quality control.

Streamlined and Efficient PCB Testing: The Future of Automated Circuit Board Testing Revealed

Automated PCB Testing Revolutionizes Electronic ManufacturingIn today's rapidly evolving technology-driven world, the demand for quality electronic products has never been greater. As companies compete to deliver innovative solutions to the market, the importance of ensuring the reliability and functionality of printed circuit boards (PCBs) cannot be overstated. To meet this demand, {Company Name}, a leading provider of advanced electronic testing solutions, has introduced a groundbreaking automated PCB testing system that promises to revolutionize the manufacturing process.With the advent of sophisticated electronic devices, the complexity of PCBs has increased exponentially. These intricate interconnections of electronic components require thorough and efficient testing to detect faults, ensure proper functionality, and reduce production costs. Traditionally, manual testing methods have been time-consuming, prone to human error, and lacked the ability to keep up with the demand for higher production volumes. This prompted {Company Name} to develop a state-of-the-art automated testing system that addresses these challenges head-on.{Company Name} is renowned for its expertise in test systems and has a long-standing reputation for pioneering innovative solutions. Their newest addition to the market is a testament to their commitment to pushing the boundaries of electronic manufacturing. Equipped with advanced technologies such as machine vision, artificial intelligence, and robotics, this automated PCB testing system offers unparalleled speed, precision, and accuracy.One of the key features of this system is its ability to detect defects with exceptional efficiency. Traditional manual testing methods are limited in their ability to detect minute faults, resulting in potential product failures or recalls. With the advanced machine vision technology incorporated into {Company Name}'s automated PCB testing system, every inch of the PCB is scrutinized, ensuring that even the tiniest flaws are detected. This level of precision greatly reduces the risk of faulty products reaching the market, thereby protecting the reputation of manufacturers and meeting customer expectations.The integration of artificial intelligence (AI) further enhances the capabilities of this automated testing system. AI algorithms analyze a vast amount of data collected during the testing process, enabling the system to identify trends, predict potential issues, and optimize testing parameters. This proactive approach not only saves time but also reduces the need for human intervention, leading to enhanced productivity and cost savings for manufacturers.Another notable advantage of {Company Name}'s automated PCB testing system is its ability to handle large-scale production volumes. Traditional manual testing methods are simply incapable of keeping pace with the industry's increasing demands. On the other hand, the automation capabilities of {Company Name}'s system allow for continuous and uninterrupted testing operations, regardless of production volume. This ensures that manufacturers can meet tight deadlines, cater to high market demand, and maintain their competitive edge.Furthermore, the integration of robotics into the testing process streamlines overall manufacturing operations. The system's robotic arms can move swiftly and precisely, reducing the time required for handling and positioning PCBs. This not only translates to accelerated production cycles but also minimizes production costs, as fewer human resources are needed for the testing process.{Company Name}'s automated PCB testing system is not only a game-changer for manufacturers but also a testament to their dedication to sustainable development. By minimizing human intervention, reducing waste, and optimizing resources, this innovative solution contributes to a greener and more sustainable manufacturing process.In conclusion, {Company Name}'s breakthrough automated PCB testing system marks a significant step forward in electronic manufacturing technology. By leveraging advanced machine vision, artificial intelligence, and robotics, this cutting-edge solution enables manufacturers to enhance product reliability, reduce production costs, and meet the ever-increasing demands of the market. With this revolutionary system, {Company Name} continues to lead the way in driving innovation and shaping the future of the electronics industry.

Discover the Shoe Sole Abrasion Tester: An Essential Tool for Evaluating Durability and Resilience

Shoe Sole Abrasion Tester Advancements Revolutionize Quality Control in the Footwear IndustryIn today's highly competitive footwear industry, product quality plays a crucial role in determining the success of a brand. With customers demanding durable and long-lasting shoes, it is imperative for manufacturers to ensure that their products meet these expectations. This is where the Shoe Sole Abrasion Tester, developed by a leading company in the sector (insert company name), comes into play. With its advanced technology and precise measurements, this innovative machine is revolutionizing quality control processes in the footwear industry.The Shoe Sole Abrasion Tester is a state-of-the-art testing instrument designed to evaluate the abrasion resistance of shoe soles. By applying friction and repeated rubbing motions, the machine simulates the wear and tear that shoes experience during daily use. The aim is to assess the durability of the sole material and determine how it will perform over time. This crucial information allows manufacturers to make informed decisions regarding the selection of materials and design features to ensure their products withstand the test of time.One of the key features of the Shoe Sole Abrasion Tester is its precision in measuring the level of abrasion. The machine is equipped with sensors that accurately record the number of cycles required to achieve a certain level of wear. This data provides manufacturers with a quantitative measurement of their product's durability. By comparing results from different materials and compositions, companies can identify the most suitable options for their footwear lines, ensuring they meet the demands of their discerning customers.Furthermore, the shoe industry has seen a rise in sustainability concerns, with consumers increasingly prioritizing eco-friendly products. The Shoe Sole Abrasion Tester addresses this issue by allowing manufacturers to evaluate the long-term performance of alternative materials before integrating them into their designs. By predicting the lifespan and durability of environmentally-friendly options, companies can make informed decisions towards a more sustainable future.The Shoe Sole Abrasion Tester is also designed to be user-friendly. Its intuitive interface allows operators of all skill levels to operate it efficiently, while the automated measuring and recording system enhances the overall efficiency of quality control processes. This convenience, combined with its accurate results, reduces the margin for error, enabling manufacturers to produce high-quality shoes consistently.The introduction of the Shoe Sole Abrasion Tester has revolutionized quality control practices in the footwear industry, allowing manufacturers to produce shoes that meet the demands of the modern consumer. With a precise measurement of abrasion resistance, companies can make informed decisions regarding material selection and design features, ensuring the durability and longevity of their products. Moreover, the machine's sustainable evaluation capabilities contribute to a more eco-friendly shoe industry, meeting the evolving needs and preferences of environmentally-conscious consumers.(insert company name), as the leading manufacturer of the Shoe Sole Abrasion Tester, has been at the forefront of this revolutionary advancement. Combining years of experience in the footwear industry with a commitment to innovation, the company has developed a product that surpasses customer expectations. By continuously refining and upgrading their testing instruments, (insert company name) enables shoe manufacturers to stay competitive in an ever-changing market.In conclusion, the Shoe Sole Abrasion Tester developed by (insert company name) has transformed quality control practices in the footwear industry. With its precise measurement capabilities, user-friendly design, and contribution to sustainability, this machine is helping manufacturers produce shoes that meet the demands of modern consumers. Sensing the need for durable and eco-friendly footwear, (insert company name) has emerged as the leader in this field, revolutionizing the manufacturing processes and ensuring the quality of shoes for years to come.