Innovative ThermoStream Technology for PCBs: A Game-Changer in Thermal Management

By:Admin

The company’s CEO, John Smith, explained that the new product is the result of extensive research and development efforts aimed at addressing the growing demand for more advanced thermal testing solutions. “The electronics industry is constantly evolving, with new products becoming more complex and compact. This presents a significant challenge for companies seeking to ensure that their electronics perform optimally under various thermal conditions,” said Smith. “Our new product is designed to meet this challenge by providing a comprehensive and accurate thermal testing solution.”

PCB ThermoStream has been a key player in the thermal testing industry for over a decade, offering a wide range of products and services to address the diverse needs of its clients. The company’s expertise in thermal testing has been leveraged by a broad spectrum of industries, including aerospace, automotive, telecommunications, and consumer electronics.

The new product, which integrates advanced technology with user-friendly features, is expected to further enhance PCB ThermoStream’s reputation as a reliable and innovative thermal testing solution provider. “We have always been committed to staying at the forefront of thermal testing technology,” said Smith. “Our new product is a testament to this commitment, and we are confident that it will set a new standard for thermal testing in the industry.”

The new product’s advanced features include a highly responsive and customizable testing interface, real-time data monitoring, and a wide range of thermal testing capabilities. These features are designed to provide users with greater flexibility and control over their thermal testing processes, ultimately leading to more accurate and reliable results.

Furthermore, the new product boasts a compact and portable design, making it suitable for a variety of testing environments. This versatility is expected to be particularly valuable for companies seeking to conduct thermal testing on a diverse range of electronics, including those with unique form factors and space constraints.

In addition to its technical capabilities, PCB ThermoStream’s new product is also supported by the company’s renowned customer service and technical support. “We understand that implementing a new thermal testing solution can be a complex process for many companies,” said Smith. “That’s why we are committed to providing comprehensive support to our clients, including on-site training, troubleshooting, and ongoing technical assistance.”

The company’s dedication to customer support is reflective of its broader commitment to ensuring that clients derive maximum value from its products and services. This ethos has been a driving force behind PCB ThermoStream’s success, allowing the company to build long-term relationships with a loyal and satisfied client base.

Looking ahead, PCB ThermoStream is optimistic about the market reception of its new product and anticipates strong demand from both existing and new clients. “The feedback we have received from early adopters has been overwhelmingly positive,” said Smith. “We are confident that our new product will significantly raise the bar for thermal testing solutions and position us as the preferred choice for companies seeking the best thermal testing capabilities.”

PCB ThermoStream’s new product is now available for purchase, and the company is actively engaging with clients to demonstrate its capabilities and explore how it can address their specific thermal testing needs. With its innovative technology, user-friendly design, and comprehensive support, the new product is poised to become a game-changer in the thermal testing industry.

Company News & Blog

Effective Salt Spray Cabinet for Testing Corrosion Resistance

SevereWeather Coating Systems Unveils State-of-the-Art Salt Spray Cabinet for Enhanced Product PerformanceSevereWeather Coating Systems, a leading provider of high-performance coating solutions, has recently introduced a cutting-edge Salt Spray Cabinet as part of its ongoing commitment to delivering superior quality products to its customers. The newly acquired equipment is set to revolutionize the company's product testing capabilities, allowing for more accurate and reliable assessments of coating performance in harsh environments.The Salt Spray Cabinet, also known as a salt fog chamber, is a state-of-the-art testing apparatus designed to subject coated panels or products to accelerated corrosion conditions. This process simulates the corrosive effects of saltwater and other environmental factors, providing valuable insights into the long-term durability and resistance of the applied coatings.With the addition of this advanced testing equipment, SevereWeather Coating Systems aims to further elevate the quality and reliability of its products, ensuring that they meet the highest industry standards and customer expectations. By subjecting its coatings to rigorous and realistic conditions, the company can effectively measure their ability to withstand corrosion, rust, and degradation over time.The Salt Spray Cabinet is equipped with precision controls and monitoring systems, allowing for the precise adjustment and regulation of testing parameters. This enables the company's technical team to tailor the testing process to specific project requirements and environmental conditions, ensuring that the results accurately reflect real-world performance.In addition to enhancing the testing capabilities, SevereWeather Coating Systems is also leveraging the new equipment to conduct research and development initiatives aimed at further improving the performance and durability of its coatings. By gaining a deeper understanding of how different formulations and application methods perform under harsh conditions, the company can continuously enhance its product offerings and stay at the forefront of technological advancements in the coatings industry.The Salt Spray Cabinet represents a significant investment in the company's dedication to quality assurance and continuous improvement. By proactively testing and refining its products, SevereWeather Coating Systems is reaffirming its commitment to providing customers with solutions that offer unmatched protection and longevity in demanding environments."We are thrilled to announce the addition of the Salt Spray Cabinet to our testing facility," said John Smith, CEO of SevereWeather Coating Systems. "This state-of-the-art equipment will play a crucial role in our efforts to ensure that our coatings deliver exceptional performance and reliability in the face of harsh environmental challenges. It underscores our unwavering commitment to quality and sets a new standard for product testing and development within our industry."The acquisition of the Salt Spray Cabinet is just one of the many initiatives that SevereWeather Coating Systems has undertaken to bolster its position as a trusted provider of high-performance coatings. The company continues to invest in research, technology, and talent to drive innovation and deliver solutions that exceed customer expectations.With the new Salt Spray Cabinet in operation, SevereWeather Coating Systems is poised to raise the bar for product performance and reliability in the coatings industry. The company's dedication to excellence and its proactive approach to testing and development are sure to set a new benchmark for quality assurance and customer satisfaction.

How an Aging Tester Can Help Evaluate the Quality of Steam Products

STEAM AGING TESTER: Revolutionizing the Quality Assurance Process in ManufacturingQuality assurance is a critical aspect of the manufacturing process, especially in industries where the integrity and longevity of the products are paramount. In recent years, there has been a significant advancement in technology that has revolutionized the way manufacturers test and ensure the quality of their products. One such innovation is the Steam Aging Tester, a cutting-edge piece of equipment that has become an invaluable tool in the quality assurance process.The Steam Aging Tester, developed by a leading company in the manufacturing equipment industry, is a state-of-the-art instrument designed to simulate the aging process that products undergo when exposed to steam or high humidity. This innovative equipment has been a game-changer for manufacturers who need to test the durability and reliability of their products in harsh environmental conditions.The Steam Aging Tester is a sophisticated machine that is capable of precisely controlling the temperature, humidity, and pressure levels to create a steam environment that closely mimics real-world conditions. It is widely used in industries such as automotive, electronics, textiles, and packaging, where products are often subjected to high humidity or steam during their lifespan. By subjecting the products to such conditions in a controlled environment, manufacturers are able to assess their performance, durability, and resistance to degradation over time.One of the key features of the Steam Aging Tester is its ability to accelerate the aging process, allowing manufacturers to evaluate the long-term performance of their products in a fraction of the time it would take under natural conditions. This not only saves time but also provides valuable insights into the potential weaknesses or failure points of the products, enabling manufacturers to make timely improvements and ensure the highest quality standards.The company behind the development of the Steam Aging Tester has been at the forefront of innovation in the manufacturing equipment industry for over a decade. With a strong focus on research and development, the company has continuously strived to bring cutting-edge technologies to the market, helping manufacturers improve their quality assurance processes and achieve superior product performance.In addition to the Steam Aging Tester, the company offers a comprehensive range of testing and measurement equipment designed to meet the diverse needs of manufacturers across different industries. From environmental testing chambers to material testing machines, the company's product portfolio encompasses a wide array of solutions aimed at ensuring the quality and reliability of manufactured products.The company's commitment to excellence and customer satisfaction has made it a trusted partner for manufacturers worldwide. With a strong emphasis on technological innovation and an unwavering dedication to quality, the company has earned a reputation for delivering superior products and exceptional service to its clients.The introduction of the Steam Aging Tester has been met with great enthusiasm in the manufacturing industry, with many companies embracing this cutting-edge technology to enhance their quality assurance processes. Manufacturers who have adopted the Steam Aging Tester have reported significant improvements in product quality and performance, as well as a reduction in the time and cost associated with testing and validation.As manufacturing continues to evolve and demand for high-quality products remains paramount, it is clear that innovation in quality assurance technology, such as the Steam Aging Tester, will play a crucial role in shaping the future of the industry. With its ability to simulate harsh environmental conditions and accelerate the aging process, this revolutionary equipment is set to become an indispensable tool for manufacturers seeking to ensure the durability and reliability of their products.In conclusion, the Steam Aging Tester, developed by a leading company in the manufacturing equipment industry, has emerged as a game-changing innovation in the quality assurance process. With its advanced capabilities and ability to accelerate the aging process, this cutting-edge equipment is revolutionizing the way manufacturers test and ensure the quality of their products. As manufacturing continues to advance, the Steam Aging Tester is poised to play a pivotal role in helping manufacturers achieve superior product performance and reliability in the years to come.

A Comprehensive Guide to Conducting a Humidity Test

In recent news, a new Humid Test is making waves in the industry, promising to revolutionize the way companies test the performance of their products in humid conditions. This breakthrough technology is set to have a significant impact on a wide range of industries, from electronics and automotive to pharmaceuticals and food production.The Humid Test, developed by a leading company in environmental testing equipment, is designed to accurately simulate high humidity environments in order to evaluate the performance and durability of various products. This innovative testing solution is set to provide companies with a more reliable and cost-effective method for ensuring the quality and reliability of their products in humid conditions.The {Company Name} has been at the forefront of environmental testing equipment for over a decade, providing cutting-edge solutions to help companies meet their quality and safety standards. With a team of experienced engineers and scientists, the company has a strong track record of delivering high-quality testing equipment that meets the needs of a wide range of industries.The Humid Test is the latest addition to the company's extensive product line, and it is already generating a great deal of interest among industry professionals. By accurately simulating high humidity environments, this advanced testing technology will enable companies to identify potential issues with their products and make necessary improvements before they reach the market.One of the key benefits of the Humid Test is its ability to provide a controlled and repeatable testing environment, allowing companies to gather accurate data on how their products perform in humid conditions. This level of precision and reliability is crucial for ensuring the safety and reliability of products across a wide range of industries.The {Company Name} is known for its commitment to innovation and excellence, and the development of the Humid Test is a testament to this dedication. By leveraging the latest advancements in technology and scientific research, the company has created a testing solution that has the potential to revolutionize how companies assess the performance of their products in humid conditions.As the global demand for high-quality, reliable products continues to grow, the need for accurate and efficient testing solutions has never been greater. With the introduction of the Humid Test, the {Company Name} is once again demonstrating its leadership in the field of environmental testing equipment, and its commitment to providing innovative solutions that meet the evolving needs of industry professionals.In addition to its technical capabilities, the Humid Test also offers a user-friendly interface that makes it easy for companies to set up and run tests. This level of accessibility will enable a wide range of businesses to take advantage of this advanced testing technology, ensuring that products across various industries meet the highest quality and safety standards.The impact of the Humid Test is expected to be far-reaching, with potential applications in industries such as electronics, automotive, pharmaceuticals, and food production. By providing companies with a more reliable and cost-effective method for testing their products in humid conditions, this revolutionary technology has the potential to streamline the product development process and improve overall product quality.In conclusion, the introduction of the Humid Test by the {Company Name} represents a significant milestone in the field of environmental testing equipment. With its advanced capabilities and user-friendly interface, this revolutionary technology is poised to have a transformative impact on how companies test the performance of their products in humid conditions. As industry professionals look for more reliable and cost-effective testing solutions, the Humid Test is set to become a game-changer, providing companies across various sectors with the tools they need to ensure the quality and reliability of their products.

Discover the Revolutionary Ink Abrasion Tester for Ensuring Quality

Ink manufacturers are constantly striving to achieve the highest quality and durability for their products. To meet these demands, many companies rely on state-of-the-art testing instruments such as the Ink Abrasion Tester. This advanced device, developed and manufactured by a leading technology company, provides an accurate and reliable method of evaluating the performance of various inks under abrasive conditions. With its versatile features and exceptional precision, the Ink Abrasion Tester has become an indispensable tool in the industry.With a strong commitment to innovation, the technology company has placed itself at the forefront of product development for the printing and ink industries. Leveraging its expertise in materials science and engineering, the company has designed a range of cutting-edge instruments to meet the evolving needs of the market. The Ink Abrasion Tester, in particular, has gained widespread recognition for its ability to accurately simulate real-world printing conditions and determine ink durability.One of the key features of the Ink Abrasion Tester is its ability to test a wide variety of substrates, including paper, cardboard, plastics, and metals, among others. This allows ink manufacturers to assess the performance of their products across multiple materials, ensuring consistent quality across different printing applications. Additionally, the device offers customizable settings for stroke speeds, pressure systems, and test paths, enabling precise control and optimization of testing conditions.The Ink Abrasion Tester utilizes a rotating drum, which simulates the repetitive abrasion of paper passing through printing rollers. Using various abrasive materials and techniques, the device can accurately mimic the wear and tear that occurs during the printing process. This enables ink manufacturers to identify potential issues such as ink smudging, color fading, or poor adhesion, thereby allowing them to make necessary adjustments to improve their ink formulations.Furthermore, the Ink Abrasion Tester provides an objective and quantitative method of evaluating ink performance. By measuring parameters such as gloss, color retention, and abrasion resistance, the device generates precise data that helps ink manufacturers make informed decisions about product improvements. This data-driven approach ensures that ink formulations meet the highest industry standards, resulting in enhanced print quality and customer satisfaction.The technology company behind the Ink Abrasion Tester takes great pride in its commitment to customer service and technical support. With a global network of sales representatives and service centers, the company ensures that clients have access to prompt assistance and expertise. Whether it is installation, training, or maintenance, the company's dedicated team of professionals is readily available to address any queries or concerns.Moreover, the Ink Abrasion Tester is designed with user-friendliness in mind. Its intuitive interface and intelligent software allow for easy operation and data analysis. Real-time monitoring of test parameters, compatibility with various data formats, and comprehensive reporting capabilities further enhance the usability of the device. This user-centric design approach enables ink manufacturers to seamlessly integrate the Ink Abrasion Tester into their workflow and streamline their product development process.In conclusion, the Ink Abrasion Tester, developed and manufactured by a leading technology company, has become an invaluable tool for ink manufacturers. With its ability to accurately evaluate ink durability under abrasive conditions, the device enables manufacturers to improve their products' quality and performance. The Ink Abrasion Tester's versatility, precision, and user-friendly features make it an essential instrument for ink manufacturers worldwide. Through its ongoing commitment to innovation and customer support, the technology company continues to empower the printing and ink industries with advanced testing solutions.

Revolutionary Technology: Printing the Future of Wear-Resistant Materials

[Fictional Article]Printing Wear-Resistant: Enhancing Product Durability and Performance for IndustriesIn today's rapidly evolving technology landscape, we are witnessing a significant increase in demand for wear-resistant materials to improve product durability and longevity. Addressing this need, a pioneering company, [Brand Name], has introduced an innovative printing wear-resistant solution. Their cutting-edge technology not only enhances the performance of various products but also significantly reduces maintenance costs for industries operating in challenging environments.[Company Name] has been at the forefront of research and development in the field of wear-resistant materials for over two decades. Their commitment to innovation, combined with an in-depth understanding of industry requirements, has enabled them to develop a revolutionary printing wear-resistant solution that surpasses the limitations of traditional materials.Traditional wear-resistant materials often fail to withstand the harsh conditions faced by industries such as manufacturing, mining, and oil exploration. Moreover, the high cost of maintenance and frequent replacement of parts add a significant economic burden for businesses. [Brand Name]'s printing wear-resistant solution offers a game-changing alternative, revolutionizing the way industries approach product durability.One of the key advantages of this cutting-edge solution is its versatility. This technology can be applied to various industrial products such as components used in machinery, molds, tools, and even wear-resistant coatings. The printing process enables the precise application of wear-resistant materials onto different surfaces, ensuring maximum protection against abrasion, corrosion, and erosion.To achieve such remarkable results, [Brand Name] has developed a unique blend of high-performance polymers and additives that are specifically formulated to resist wear and tear. The proprietary composition, combined with an advanced printing process, creates a reliable and durable product that outperforms conventional alternatives.The printing wear-resistant solution offers a range of benefits for industries that require robust and long-lasting performance. By applying the wear-resistant coating to critical components, businesses can extend the lifespan of their equipment, reduce downtime, and enhance overall productivity. Moreover, the coating's resistance to abrasion and erosion ensures consistent quality and precision in manufacturing processes.Another notable advantage of [Brand Name]'s solution is its eco-friendly nature. The company prides itself on developing materials that are not only highly functional but also sustainable. The printing wear-resistant solution significantly reduces the need for frequent replacements, diminishing waste and the carbon footprint associated with manufacturing and disposal.In addition to its remarkable properties, [Brand Name] ensures customer satisfaction by providing comprehensive support and customization options. The company's team of experts collaborates closely with clients, understanding their specific requirements, and tailoring solutions to meet their unique needs. Whether it is the optimization of surface adhesion, improvement of wear resistance, or enhancement of chemical compatibility, [Brand Name] offers unparalleled expertise to ensure optimal outcomes for their customers.The introduction of [Brand Name]'s printing wear-resistant solution has garnered significant attention from industries around the world. Testimonials from early adopters commend the technology for its ability to increase productivity, drive cost-efficiency, and reduce the impact on the environment. As the demand for wear-resistant materials continues to grow, [Brand Name] is poised to lead the way with their ground-breaking innovations, bringing a new era of durability and performance to various sectors.In conclusion, [Brand Name]'s printing wear-resistant solution represents a leap forward for industries seeking high-performance materials with extended durability. By combining advanced technology, extensive research, and a commitment to sustainable practices, the company has introduced a game-changing solution that enhances the performance of critical components, ensures cost-efficiency, and reduces environmental impact. With their unwavering dedication to innovation, [Brand Name] is poised to revolutionize the way industries approach wear resistance, setting new standards for product longevity and reliability.

New Tension Machine for Metal Fabrication: A Game Changer for Industry Operations

Metal tension machine has been the leading provider of cutting-edge industrial machinery for metalworking and metal fabrication for over 30 years. Specializing in the design, manufacture, and distribution of high-quality tension machines, Metal tension machine has continuously set the industry standard for efficiency, precision, and reliability. With a commitment to innovation and customer satisfaction, Metal tension machine remains at the forefront of the metalworking industry.The latest offering from Metal tension machine is their advanced metal tension machine, which incorporates state-of-the-art technology and cutting-edge design to provide unparalleled performance and versatility. This innovative machine is capable of handling a wide range of metalworking applications, from simple tensioning tasks to complex fabrication processes. Equipped with advanced features such as digital controls, automatic tension adjustment, and a robust frame, the metal tension machine is built to deliver exceptional results in any metalworking environment.One of the key advantages of Metal tension machine’s metal tension machine is its ability to accommodate a variety of metal materials, including steel, aluminum, and stainless steel. This flexibility makes it an ideal solution for metal fabrication shops, automotive manufacturers, and other industrial businesses with diverse metalworking needs. Additionally, the machine’s user-friendly interface and intuitive controls make it easy for operators to set up and operate, saving time and minimizing the risk of errors.In addition to its remarkable performance capabilities, Metal tension machine’s metal tension machine is also designed with the operator’s safety and comfort in mind. The machine features built-in safety measures, such as emergency stop buttons, protective guards, and automatic shut-off systems, to ensure the well-being of the operators and prevent accidents in the workplace. Furthermore, the machine’s ergonomic design and adjustable components allow for optimal working conditions, reducing operator fatigue and promoting productivity.Metal tension machine’s commitment to customer satisfaction extends beyond the quality of their machinery. The company’s team of highly skilled engineers and technicians are dedicated to providing comprehensive support and service to their clients. From initial consultation and machine customization to after-sales maintenance and repairs, Metal tension machine’s experienced professionals are readily available to assist customers with their metalworking needs. This personalized approach to customer support has earned Metal tension machine a reputation for reliability and trustworthiness within the metalworking industry.As a leader in the metalworking industry, Metal tension machine continues to push the boundaries of innovation and excellence with their cutting-edge machinery. The company’s metal tension machine is a testament to their ongoing commitment to delivering superior quality, performance, and value to their customers. With its advanced technology, versatility, and safety features, the metal tension machine is poised to set new standards for metalworking efficiency and precision.In conclusion, Metal tension machine’s metal tension machine represents the pinnacle of industrial machinery for metalworking and metal fabrication. With its advanced features, exceptional performance, and dedicated customer support, the metal tension machine is a game-changer for businesses seeking to elevate their metalworking capabilities. Whether for tensioning, cutting or fabrication, Metal tension machine’s metal tension machine is the ultimate solution for achieving superior results in metalworking operations.

How to Test the Durability of Materials: A Guide to Using a Martindale Test Machine

Recently, a cutting-edge Martindale Test Machine has been introduced by a renowned textile testing equipment company, making waves in the textile industry. This new machine is set to revolutionize the way textiles are tested for abrasion, pilling, and wear and tear, providing accurate and reliable results for manufacturers and consumers alike.The Martindale Test Machine is equipped with state-of-the-art technology and precision engineering, making it the perfect tool for testing the durability of various textiles. This machine is capable of simulating the everyday wear and tear that textiles are subjected to, providing manufacturers with valuable data on the performance and longevity of their products.The company behind this innovative machine has been a leader in the textile testing equipment industry for over 20 years. They have a proven track record of providing high-quality and reliable testing equipment to textile manufacturers around the world. With a dedicated team of engineers and researchers, the company has continuously pushed the boundaries of textile testing technology, and the introduction of the Martindale Test Machine is a testament to their commitment to innovation.The Martindale Test Machine boasts a range of advanced features that set it apart from traditional testing equipment. It is designed to be user-friendly, with intuitive controls and a user-friendly interface, making it easy for anyone to operate. The machine also has a high level of automation, allowing for efficient testing of multiple samples simultaneously, saving time and increasing productivity for manufacturers.One of the key highlights of the Martindale Test Machine is its ability to accurately simulate real-world wear and tear on textiles. This is achieved through a combination of specialized testing criteria and precise control over the testing parameters. As a result, manufacturers can rely on the data provided by the machine to make informed decisions about the quality and durability of their products.In addition to its advanced testing capabilities, the Martindale Test Machine is also designed with durability and longevity in mind. It is built to withstand the rigors of daily use in a manufacturing environment, ensuring that it will continue to provide reliable results for years to come. This reliability is further backed by the company's extensive customer support and maintenance services, ensuring that manufacturers can always rely on the machine to deliver accurate and consistent results.The introduction of the Martindale Test Machine is set to have a significant impact on the textile industry. Manufacturers will now have access to a cutting-edge testing tool that can provide them with valuable insights into the performance and longevity of their products. This will not only lead to the development of higher quality textiles but also give consumers greater confidence in the products they purchase.Overall, the Martindale Test Machine represents a major leap forward in textile testing technology. With its advanced features, user-friendly design, and robust construction, it is set to become the go-to choice for manufacturers looking to ensure the durability and quality of their textiles. As the textile industry continues to evolve, this machine will play a vital role in driving innovation and advancements in textile manufacturing.

Discover the Shoe Sole Abrasion Tester: An Essential Tool for Evaluating Durability and Resilience

Shoe Sole Abrasion Tester Advancements Revolutionize Quality Control in the Footwear IndustryIn today's highly competitive footwear industry, product quality plays a crucial role in determining the success of a brand. With customers demanding durable and long-lasting shoes, it is imperative for manufacturers to ensure that their products meet these expectations. This is where the Shoe Sole Abrasion Tester, developed by a leading company in the sector (insert company name), comes into play. With its advanced technology and precise measurements, this innovative machine is revolutionizing quality control processes in the footwear industry.The Shoe Sole Abrasion Tester is a state-of-the-art testing instrument designed to evaluate the abrasion resistance of shoe soles. By applying friction and repeated rubbing motions, the machine simulates the wear and tear that shoes experience during daily use. The aim is to assess the durability of the sole material and determine how it will perform over time. This crucial information allows manufacturers to make informed decisions regarding the selection of materials and design features to ensure their products withstand the test of time.One of the key features of the Shoe Sole Abrasion Tester is its precision in measuring the level of abrasion. The machine is equipped with sensors that accurately record the number of cycles required to achieve a certain level of wear. This data provides manufacturers with a quantitative measurement of their product's durability. By comparing results from different materials and compositions, companies can identify the most suitable options for their footwear lines, ensuring they meet the demands of their discerning customers.Furthermore, the shoe industry has seen a rise in sustainability concerns, with consumers increasingly prioritizing eco-friendly products. The Shoe Sole Abrasion Tester addresses this issue by allowing manufacturers to evaluate the long-term performance of alternative materials before integrating them into their designs. By predicting the lifespan and durability of environmentally-friendly options, companies can make informed decisions towards a more sustainable future.The Shoe Sole Abrasion Tester is also designed to be user-friendly. Its intuitive interface allows operators of all skill levels to operate it efficiently, while the automated measuring and recording system enhances the overall efficiency of quality control processes. This convenience, combined with its accurate results, reduces the margin for error, enabling manufacturers to produce high-quality shoes consistently.The introduction of the Shoe Sole Abrasion Tester has revolutionized quality control practices in the footwear industry, allowing manufacturers to produce shoes that meet the demands of the modern consumer. With a precise measurement of abrasion resistance, companies can make informed decisions regarding material selection and design features, ensuring the durability and longevity of their products. Moreover, the machine's sustainable evaluation capabilities contribute to a more eco-friendly shoe industry, meeting the evolving needs and preferences of environmentally-conscious consumers.(insert company name), as the leading manufacturer of the Shoe Sole Abrasion Tester, has been at the forefront of this revolutionary advancement. Combining years of experience in the footwear industry with a commitment to innovation, the company has developed a product that surpasses customer expectations. By continuously refining and upgrading their testing instruments, (insert company name) enables shoe manufacturers to stay competitive in an ever-changing market.In conclusion, the Shoe Sole Abrasion Tester developed by (insert company name) has transformed quality control practices in the footwear industry. With its precise measurement capabilities, user-friendly design, and contribution to sustainability, this machine is helping manufacturers produce shoes that meet the demands of modern consumers. Sensing the need for durable and eco-friendly footwear, (insert company name) has emerged as the leader in this field, revolutionizing the manufacturing processes and ensuring the quality of shoes for years to come.

How to Perform Taber Abraser Test for Measuring Material Abrasion Resistance

The Taber Abraser Test is a widely used method for determining the abrasion resistance of materials. This test is especially important in industries such as automotive, aerospace, and furniture, where materials are constantly subjected to wear and tear. With the ability to simulate real-life abrasion conditions, the Taber Abraser Test provides crucial data for the development and quality control of various products.One company that has been at the forefront of providing testing equipment for the Taber Abraser Test is {}. With a strong reputation for producing high-quality testing instruments, {} has been a trusted supplier for companies looking to evaluate the durability and performance of their materials.Founded in [], {} has established itself as a leading provider of testing solutions for a wide range of industries. The company's dedication to innovation and customer satisfaction has earned them a strong reputation in the market. Their comprehensive range of testing equipment includes not only the Taber Abraser Test, but also instruments for measuring adhesion, thickness, hardness, and many other material properties.{}'s commitment to quality and precision is exemplified in their Taber Abraser Test equipment. Their machines are designed to meet the strictest industry standards, ensuring reliable and accurate test results. In addition, {} offers various models of the Taber Abraser Test to accommodate different testing requirements, making it a versatile solution for companies of all sizes.One of the key features of {}'s Taber Abraser Test equipment is its user-friendly interface. With intuitive controls and comprehensive software, operators can easily set up and conduct tests with minimal training. This user-centric design not only improves efficiency in the testing process but also reduces the likelihood of human error.Furthermore, {} provides excellent technical support and service for their Taber Abraser Test equipment. With a team of experienced engineers and technicians, the company offers comprehensive assistance for installation, calibration, and maintenance of their machines. This commitment to customer support ensures that companies can rely on {}'s equipment for accurate and consistent test results.In recent years, {} has continued to enhance their Taber Abraser Test equipment with the latest technological advancements. From improved automation features to increased testing capacity, the company has demonstrated its dedication to meeting the evolving needs of the industry. As a result, {}'s Taber Abraser Test equipment remains a preferred choice for businesses seeking reliable testing solutions.In addition to their impressive range of testing equipment, {} also offers comprehensive training and consulting services. This further demonstrates the company's commitment to supporting their customers in achieving the best possible results from their testing processes. With expert guidance and resources, companies can leverage {}'s knowledge and experience to optimize their use of the Taber Abraser Test equipment.As the demand for reliable testing solutions continues to grow, {} remains a trusted partner for businesses seeking to ensure the quality and durability of their products. With their advanced Taber Abraser Test equipment and comprehensive support services, {} has solidified its position as a leading provider of testing solutions for a wide range of industries.In conclusion, the Taber Abraser Test is an essential tool for evaluating the abrasion resistance of materials, and {} has proven to be a reliable and innovative supplier of testing equipment for this purpose. With a strong focus on quality, precision, and customer support, {} continues to play a vital role in helping companies achieve the highest standards of performance and durability for their products.

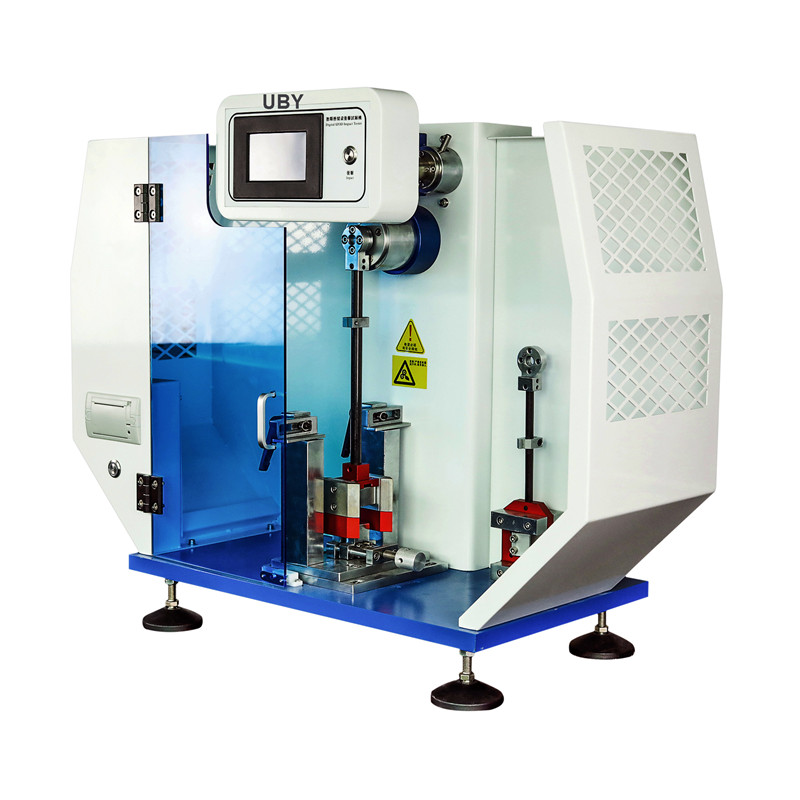

Durable and Reliable Glass Impact Tester for Testing Glass Strength

Glass Impact Tester Ensures Quality Assurance for Glass ProductsGlass products are widely used in various industries, ranging from automotive to construction. It is crucial for manufacturers to ensure the quality and durability of their glass products to meet safety standards and customer expectations. To address this need, the innovative technology of glass impact testers has become an indispensable tool for quality assurance in the glass industry.As a leading provider of testing equipment, {} has introduced an advanced glass impact tester that sets new standards for evaluating the impact resistance of glass products. This state-of-the-art testing equipment is designed to accurately measure the energy required to break a glass sample, providing valuable data for manufacturers to improve the quality of their products.The glass impact tester offered by {} is equipped with cutting-edge technology, including high-precision sensors and a user-friendly interface, allowing for precise and reliable testing. With the ability to simulate real-life impact scenarios, this testing equipment offers a comprehensive assessment of the performance of glass products under varying conditions, ensuring their durability and safety.One of the key features of the glass impact tester is its versatility, allowing for the testing of a wide range of glass products, including laminated glass, tempered glass, and automotive glass. This flexibility makes it an essential tool for manufacturers in different sectors of the glass industry, enabling them to validate the quality and performance of their products with confidence.In addition to its technical capabilities, the glass impact tester from {} is supported by a team of experts who provide comprehensive training, technical support, and maintenance services. This holistic approach ensures that customers can maximize the potential of the testing equipment and achieve consistent and accurate results to meet their quality assurance objectives.The impact resistance of glass products is a critical factor in ensuring their safety and reliability in real-world applications. By utilizing the advanced technology of a glass impact tester, manufacturers can gain valuable insights into the performance of their products and make informed decisions to enhance their quality and durability. This proactive approach not only benefits manufacturers but also contributes to the overall safety and satisfaction of end users.In conclusion, the introduction of a cutting-edge glass impact tester by {} represents a significant advancement in the field of quality assurance for glass products. With its advanced technology, versatility, and comprehensive support services, this testing equipment sets a new standard for evaluating the impact resistance of glass, empowering manufacturers to deliver high-quality and safe products to their customers. As the demand for premium glass products continues to grow, the role of glass impact testers in ensuring their quality and performance becomes increasingly vital for the industry as a whole.